The year is winding down and I wanted to get some longterm planning done. I created a calendar for May and June and filled in each block with the lessons that I would cover each day. Originally, I planned on doing a few general lessons on simple machines, then dedicating the next six school days to a more detailed study of each simple machine: inclined planes, wheels and axles, wedges, screws, pulleys and levers. Within a few days, this plan was scrapped.

Once we had explored each of the six simple machines, I didn't think the students could bear an in-depth study of each for the next week. It was boring and I didn't think that they would retain as much as I had hoped. Before even beginning with the plan, I decided to hold a mini-competition instead.

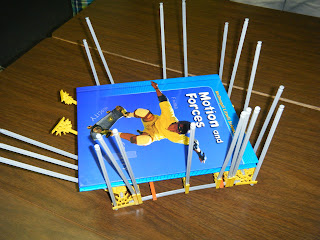

Our science department is fortunate enough to own two giant tubs of K'Nex building materials. The kits were intended for building a roller coaster, but I wanted something simpler and more focused for our goals. I broke up our class into two groups and gave each group a task. One group was responsible for constructing a cart large enough and strong enough for moving the science textbook. They were given total freedom as far as design because students come with so much background knowledge already about carts, cars and wheels.

The second group was responsible for constructing a pulley strong enough to lift two metal weights. I showed the weights to the group so that they were fully aware of the load that their pulley had to carry. I also gave them a booklet that came from with the K'Nex kit about constructing pulleys. They were allowed to use the photos in the booklet for reference, but their pulley did not have to follow the directions exactly. The weight that they had to lift was significantly larger than the weight featured in the photo, so they had to adapt their creation to accommodate more weight. I was pleased to see that none of the groups copied the model exactly and that they all added features that they thought would increase the machine's efficiency.

The two groups constructed their pieces simultaneously, then we tested the pieces and kept lab data about how much force was needed to pull the loads. We used a spring scale to measure how much force was required to move the textbook without any machine, then we measured how much force was required to move the textbook with the help of the cart. In most cases, the students constructed carts that were provided significant mechanical advantage.

We used the spring scale again to measure how much force was needed to lift the weights with no assistance, then we used the spring scale to measure how much force was needed to pull the rope through the pulley. Most of the pulleys had only marginal mechanical advantage, but I explained how adding more pulleys can increase the advantage and decrease the amount of effort.

Once our machines had been tested and we recorded the data into the lab sheets, we disassembled the machines and switched roles. The cart team was now responsible for constructing a pulley, and the pulley team for a cart. The new machines were tested and compared to the first round of machines.

Within the parameters that I described, the students, for the most part, worked cooperatively and built machines that met or exceeded my expectations. Rather than spending two days teaching wheels and axles and pulleys to the students, they experienced the concepts hands-on.

Subscribe to:

Post Comments (Atom)

0 comments:

Post a Comment